Sep 14, 2024

Sep 14, 2024

Liquid nitrogen quick freezing machine is a equipment that uses liquid nitrogen as the freezing medium. The boiling point of liquid nitrogen under normal pressure is -196°C. Therefore, liquid nitrogen quick freeze machine can usually provide operating temperatures as low as -120°C or even -150°C (Crust Freezing), while the working temperature of ordinary compressor quick freezing machines is only -35°C to -40°C. As an advanced ultra-low temperature freezing equipment, liquid nitrogen quick freezing machine has brought great changes to the food industry with its fast, uniform and efficient freezing capabilities, providing consumers with higher quality frozen food.

The core principle of the liquid nitrogen quick freezing machine is to use the ultra-low temperature characteristics of liquid nitrogen to achieve rapid freezing. When the liquid nitrogen comes into contact with the food, it will quickly absorb the heat on the surface of the food, allowing the food to reach the freezing temperature in a short time. The entire process of freezing food as follows:

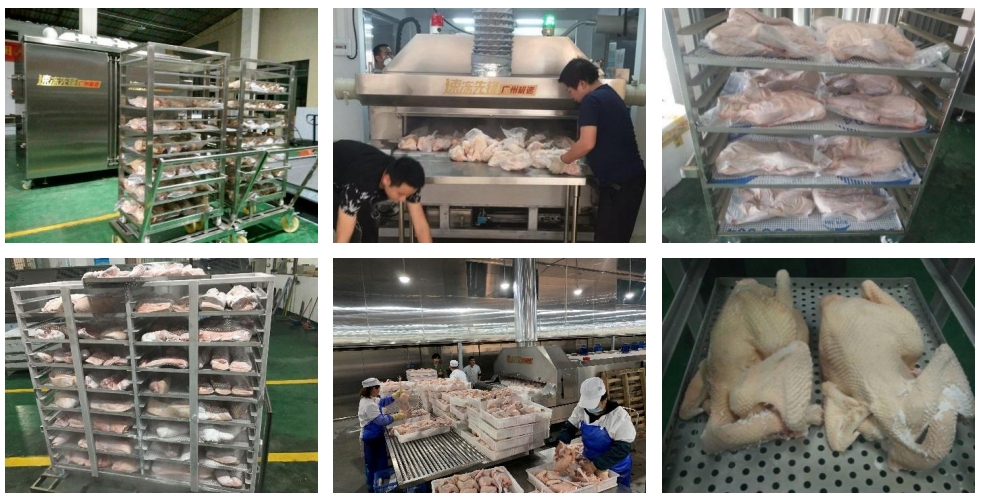

1. Preprocessing: Before food enters the quick-freezing machine, it usually needs to undergo preprocessing steps such as cleaning and cutting to ensure the quick-freezing effect and food quality. The purpose of preprocessing is to remove surface dirt and impurities while cutting the food into appropriate sizes to ensure uniform freezing and shorter freezing time.

2. Put it into the freezing area: The preprocessed food is put into the liquid nitrogen quick freeze machine. The quick freezing cabinet is equipped with multiple liquid nitrogen nozzles or spray devices to ensure that liquid nitrogen can evenly cover the food surface. When entering the freezing area, the temperature of the food is usually close to room temperature or slightly lower, making the initial stages of the freezing process extremely critical.

3. Liquid nitrogen spraying: In the freezing area, liquid nitrogen comes into contact with the food surface by spraying. Liquid nitrogen quickly absorbs heat and vaporizes after contacting the food surface, forming a freezing effect. The spraying process requires accurate control to ensure that liquid nitrogen can fully cover the surface of the food to achieve rapid freezing.

4. Rapid cooling: During the spraying of liquid nitrogen, the temperature of the food surface drops rapidly. Due to the ultra-low temperature characteristics of liquid nitrogen, the moisture on the surface of the food freezes quickly, forming fine ice crystals. This rapid cooling process minimizes the rupture of food cells and maintains the texture and taste of the food. The key in the cooling process is to control the flow rate and spray time of liquid nitrogen to ensure that the food can be frozen evenly and thoroughly.

5. Layer-by-layer freezing: For larger or thicker foods, liquid nitrogen quick freezing machines usually use layer-by-layer freezing. This means that the surface of the food freezes first, and then the freezing layer gradually expands toward the interior until the entire food reaches the desired freezing temperature. The advantage of layer-by-layer freezing is that it can ensure that the inside and outside of the food are fully frozen without the problem of the center part not being completely frozen.

6. Quick freezing completed: In a very short period of time, the temperature of the food quickly drops below -18 degrees Celsius, and the water in the cells freezes quickly to form fine ice crystals, maintaining the original texture and flavor of the food to the maximum extent. The entire freezing process usually only takes a few minutes to ten minutes, which is much faster than traditional freezing methods.

7. Discharge: After the quick freezing is completed, the food is sent out of the quick freezing machine and enters the subsequent packaging and storage links. When discharging, the surface temperature of the food has dropped to a very low level, so care must be taken to avoid secondary heating or population. The discharging link is usually equipped with automated equipment to transport quick-frozen food to the packaging line for sealing, packaging and labeling.

1. Will Liquid Nitrogen Quick Freezing Affect The Nutrition of Food?

No, liquid nitrogen quick freezing technology is an efficient method to maintain the nutritional value of food. Liquid nitrogen quick freezing technology can reduce the temperature of food to -196°C in a very short time. This rapid cooling can prevent the moisture inside the food from forming large ice crystals, thereby reducing damage to the cell structure and maintaining the texture and nutrients of the food. Due to the rapid freezing process, nutrients such as vitamins and minerals in food can be better retained during the quick freezing process. Compared with traditional freezing methods, liquid nitrogen quick freezing can minimize the loss of nutrients. The ultra-low temperature environment can effectively restrain the growth of microorganisms and enzyme activity, thereby extending the shelf life of food and maintaining its freshness and nutritional value.

2. Is the Maintenance Cost of Liquid Nitrogen quick freeze machine High?

SPEEDCRYO is a cold chain equipment manufacturer with more than 10 years of experience. SPEEDCRYO is committed to providing efficient and durable quick freeze machine to minimize customers' maintenance costs. SPEEDCRYO's equipment uses advanced design and high-quality materials to ensure that it maintains excellent performance under long-term and high-intensity use. SPEEDCRYO provides detailed use and maintenance manuals, and provides customers with regular technical training and support to help customers operate and maintain equipment correctly. In addition, SPEEDCRYO also provides regular preventive maintenance services to detect and solve potential problems in time to avoid production stagnation and additional maintenance costs caused by equipment failure. Through these measures, SPEEDCRYO ensures that customers can enjoy low maintenance costs and high production efficiency when using our liquid nitrogen quick freeze machine.

3. How to choose a liquid nitrogen quick freezer suitable for your business?

When choosing a liquid nitrogen quick freezer, you should consider the specific needs of your own business, such as food type, production volume, freezing speed, etc. SPEEDCRYO is a liquid nitrogen quick freeze machine supplier with over ten years of manufacturing experience. We provide two types of liquid nitrogen quick freeze machine, tunnel type and cabinet type. The length of tunnel type liquid nitrogen quick freeze machine ranges from 7 meters to 24 meters, and the width of the quick freezing belt can range from 0.8 meters to 2 meters. We provide single door, double door, four door cabinet type liquid nitrogen freezing machine, fully meet the needs of different processing scale.

Here you can learn more about the introduction of cabinet-type liquid nitrogen quick freeze machine:

Small Stand up Liquid Nitrogen Freezer

Here you can learn more about tunnel-type liquid nitrogen quick freezing: