Salmon, celebrated for its refined flavor profile and rich nutritional composition, occupies a distinguished position in high-quality food. However, the dual nature of its high market value and delicate structure poses a multifaceted challenge in preserving its freshness and quality.

Freshness and quality are pivotal factors influencing consumer acceptance and demand. Preserving the natural attributes of salmon becomes paramount to meeting the discerning expectations of the market.

This in-depth analysis delves into the unique attributes of salmon, the challenges posed by traditional freezing methods, and the transformative advantages offered by industrial liquid nitrogen tunnel freezing.

Salmon boasts a multifaceted profile that demands careful consideration during the freezing process. Its distinctive characteristics include a fragile texture, elevated fat content—essential for flavor and health benefits—and a nutrient composition that contributes to its superfood status. The interplay of these elements requires a nuanced approach to ensure that each facet is preserved with the utmost precision.

The delicate balance of flavors and textures in salmon necessitates a preservation method that not only safeguards its tender structure but also retains its nutritional richness. The elevated fat content, a source of its luscious taste, requires a specialized freezing technique to prevent undesirable alterations during the freezing process.

Preserving the inherent qualities of salmon during freezing is an intricate task due to its unique characteristics. The fragility of its texture makes it susceptible to damage from conventional freezing methods, leading to a loss of integrity and compromising the overall eating experience. Moreover, the challenge is compounded by the heightened fat content, which can undergo undesirable changes, affecting both taste and nutritional value.

The freezing process must tread carefully to avoid ice crystal formation, which could disrupt the delicate cellular structure of salmon, resulting in compromised texture and diminished quality. The challenge lies in finding a method that not only meets the stringent demands of preservation.

1. Ice Crystal Damage

Traditional freezing methods introduce the risk of ice crystal formation, compromising the delicate structure of salmon. This leads to a coarser texture, diminishing the taste appeal.

2. Nutrient Loss

Prolonged exposure to suboptimal freezing conditions can result in nutrient loss, impacting the health benefits of salmon. Essential components, such as Omega-3 fatty acids, are vulnerable to degradation.

3. Surface Freezing Issues

Uneven cooling often leads to surface freezing problems, causing "freezer burn" and altering the appearance and flavor of salmon. This not only diminishes its visual appeal but also detracts from the overall taste experience.

1. Ultra-Rapid Cooling Precision

Liquid nitrogen tunnel freezing heralds a new era in salmon preservation through its unparalleled speed in cooling. The technology achieves ultra-rapid freezing rates, swiftly bringing the entire fish to the desired temperature. This precision is vital in circumventing cellular damage, ensuring the structural integrity of the salmon remains intact.

2. Cellular Preservation

The rapid cooling kinetics of liquid nitrogen play a pivotal role in preserving the delicate cellular structure of salmon. Unlike traditional methods, which risk ice crystal formation, this advanced freezing technique forms microcrystals that do not disrupt the cellular matrix. The result is a salmon product with a texture akin to fresh, maintaining the essence of its taste appeal.

3. Nutrient Lockdown

Liquid nitrogen tunnel freezing stands as a guardian of the nutritional profile of salmon. The swift cooling process not only mitigates the risk of nutrient loss but actively locks in the essential components that define salmon as a nutritional powerhouse. Omega-3 fatty acids, vitamins, and minerals are preserved at optimal levels, ensuring the end product maintains its status as a superfood.

4. Pristine Taste Preservation

Preserving the pristine taste of fresh salmon is a hallmark of liquid nitrogen tunnel freezing. By minimizing the formation of large ice crystals, the technology ensures that the natural flavors of the fish remain unaltered. The result is a frozen salmon product that mirrors the taste profile of its fresh counterpart, offering an unparalleled culinary experience.

5. Consistency through Intelligent Systems

Liquid nitrogen tunnel freezing leverages intelligent systems that go beyond rapid cooling. These systems optimize freezing parameters and time, ensuring a consistent and high-quality end product. Automation minimizes the risk of human error, contributing to a streamlined and efficient freezing process.

6. Enhanced Aesthetic Appeal

The application of liquid nitrogen tunnel freezing contributes to the visual allure of frozen salmon. By preventing surface freezing issues and freezer burn, the technology preserves the aesthetic integrity of the fish. The end product boasts a pristine appearance that is visually enticing to consumers.

A comprehensive cost-benefit analysis reveals that liquid nitrogen tunnel freezing not only boosts production capacity but also reduces waste and losses. The investment yields significant returns, positioning it as a financially viable solution.

Enhanced Freezing Efficiency

Utilizing a liquid nitrogen tunnel freezer significantly boosts freezing efficiency, minimizing losses incurred during waiting times. This translates to reduced food quality degradation and mitigates the risk of spoilage, ensuring optimal product quality.

Full Automation for Streamlined Production

The implementation of a liquid nitrogen tunnel freezer introduces full automation, streamlining production processes. This not only shortens freezing durations but also results in a reduction in the number of operational staff required and overall shift times, enhancing operational efficiency.

Elevated Product Quality and Market Positioning

The advanced freezing capabilities of the tunnel freezer contribute to an improvement in the quality of frozen food ingredients, enabling businesses to position their products at a higher tier in the market. This, in turn, facilitates the potential for increased sales prices, enhancing overall economic returns for the enterprise.

We do have experience exporting our tunnel freezers overseas. Engineered to be seamlessly transported as complete units, these tunnels are meticulously commissioned and tested before shipment. Upon arrival, customers need only connect the liquid nitrogen pipes, exhaust pipes, and power cables to initiate seamless freezer operation.

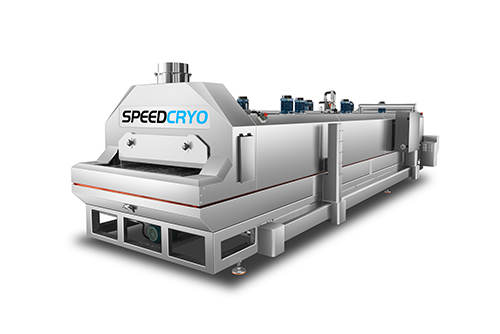

800kg/hour Cryogenic Freezing Tunnel as an example:

Overall Size: 11 meters in length, 2.2 meters in width, 1.7 meters in height;

Freezing / Belt Running Time: 18~30 minutes/ batch / about 230 pieces Whole Salmon;

Freezing temperature maintained between -100°C to -130°C.

Our clients express unparalleled satisfaction with both the speed of freezing and the exceptional quality of their frozen products. In comparison to traditional freezing methods, where each batch could take a minimum of 4 hours, our cutting-edge SPEEDCRYO® Tunnel Freezer drastically reduces the freezing time, nearly 10 times faster. This transformative efficiency not only eliminates the need for a two-shift workforce but allows our clients to accomplish their freezing tasks with just one shift.

The streamlined process not only impresses with its efficiency but also garners praise for the consistently high quality of the frozen items. Clients have enthusiastically embraced the solution, repeatedly investing in our quick freezing tunnel equipment to meet the ever-growing demands of their expanding production capacities.

Witness a revolution in both production efficiency and freezing quality with SPEEDCRYO®. Our clients' resounding endorsement stands testament to the profound impact our rapid freezing solutions have on optimizing operations and satisfying the increasing needs of their enterprises.

Liquid nitrogen tunnel freezing emerges as the pinnacle of salmon preservation methods, aligning perfectly with market demands and elevating the product's market positioning. It sets a new standard for quality, ensuring that salmon reaches consumers in optimal condition.

Contact us today to embark on a journey of enhancing your product quality, meeting market demands, and securing a prominent position in the industry. Elevate your salmon production with cutting-edge freezing technology - the choice for excellence.