PRODUCT MAIN SPECIFICATIONS

| Type: |

Liquid Nitrogen Freezer |

| Model No.: |

JSGS-6000L |

| External Dimensions: |

3020x2190x2370 mm (LxWxH) |

| Internal Dimensions: |

1175x1400x1750 mm ( x 2 cabinets) |

| Working Temperature: |

0 to -120 degrees Celcius |

| Average Capacity: |

700-1400 KG/H (normal ingredients)

1000 KG/Cycle (whole durian)

600-840 KG/Cycle (durian pulp)

|

| Power: |

1.5KW, 380v/400v, 3P |

| ACCESSORY (A) - FOR NORMAL FOODS |

| Shelf: |

2 units, SUS304, 1266x820x1490 mm |

| Trolley: |

2 units, SUS304 |

| Tray: |

120 pieces, 400x600 mm, SUS304 |

| Inter-Layer Spacing: |

100 mm |

| ACCESSORY (B) - FOR WHOLE DURIAN |

| Durian Cart: |

2 units, SUS304 |

| Trolley: |

2 units, SUS304 |

SPEEDCRYO® Cabinet-Type Liquid Nitrogen Freezer JSGS-6000L offers two types of accessories: a standard tray + shelf and a durian cage. The tray + shelf setup is suitable for most common ingredients, such as seafood, fruits, baked goods, and prepared foods. The durian cage is specifically designed for freezing whole durians. Users can choose the appropriate accessory based on their needs, or they can purchase both types of accessories simultaneously.

ACCESSORY (A) - FOR NROMAL FOODS

-

Shelf

Inter-layer spacing 100mm, 60 trays per shelf. Inter-layer spacing adjustable.

-

Trolley

Trolley for loading, discharging and moving the shelves.

-

Tray (400x600mm)

High quality SUS304 stainless trays, 120 pieces of tray loaded per batch

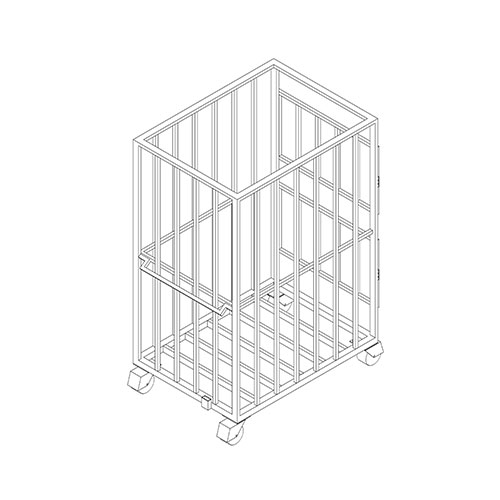

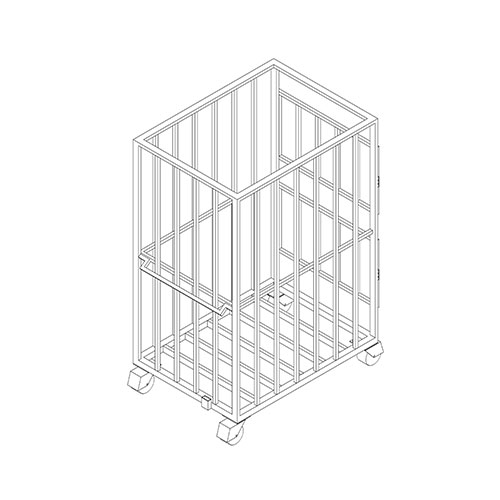

ACCESSORY (B) - FOR WHOLE DURIAN

-

Durian Cart

SUS304 durian cart, 700-800 kg of whole durian can be loaded in each cart.

-

Trolley for Durian Cart

SUS304 trolley, for loading, discharging and moving durian carts.

APPLICATIONS OF SPEEDCRYO® LIQUID NITROGEN FREEZER

SPEEDCRYO's liquid nitrogen cabinet freezer is widely used for freezing whole durians, durian pulp, seafood (fish, shrimp, crabs, sea cucumbers, abalone, Arctic surf clams, salmon, etc.), baked goods (egg tarts, durian cakes, ice cream, etc.), prepared foods, and more. Operating in a temperature range from 0°C to -120°C, it meets the rapid freezing needs of most foods. Despite its compact size, it offers higher capacity, low initial investment costs, low maintenance costs, and ease of use. The ultra-low operating temperatures result in smaller ice crystals, better quality frozen products, and longer shelf life. Foods frozen with SPEEDCRYO's liquid nitrogen freezer retain their color, texture, and nutritional value close to their fresh state after thawing. Consequently, more food companies, especially those dealing with high-end products, are increasingly adopting liquid nitrogen freezing technology to replace traditional compressor-based freezing equipment.

Overview of Industrial liquid nitrogen (LN2) Cryogenic Freezers

Industrial LN2 cryogenic freezers are engineered for large-scale, high-volume food manufacturing applications where ultra-fast freezing speed is critical for maximizing production throughput and frozen product quality.

We customize solutions utilizing direct liquid nitrogen injection at -320°F/-196°C to achieve conductive freezing times up to 10X faster than traditional mechanical systems. Items are put inside the chamber and immersed in nitrogen vapors, chilling products to a frozen state within minutes.

Precise process controls of liquid nitrogen flow based on product load and zones ensures optimal cryogen usage efficiency. Advanced data logging allows for monitoring and analyzing thermal transfer rates.

Available capacities range from 50kg/hour to over 3,000kg/hour. Various chamber dimensions accommodate different product sizes and line layouts. Rugged stainless steel construction with minimal crevices and fully rounded corners simplifies sanitation procedures.

Small Size Mechanical Cryogenic Freezers

In addition to industrial-scale units, we manufacture compact mechanical cryogenic freezers designed for small-batch artisanal freezing operations. These tabletop units with capacities between 50-300kg/hour reach cryogenic freezing temperatures down to -320°F/-196°C, twice as cold as traditional mechanical freezers.

The insulated freezing chambers allow the loading of products into specialty racks and trays. While utilizing instant liquid nitrogen injection, the direct conductive contact with cryogen-liquid nitrogen facilitates rapid freezing cycles in under 10~30 minutes for small items.

Touchscreen controls allow easy programming of batch freezing cycles and data tracking. Their minimal footprint and simple interface are ideal for R&D scale testing and intermittent short production runs.

Price of Cryogenic Freezers

Pricing for our industrial liquid nitrogen cryogenic freezers varies based on capacity, features, and options:

- Small tabletop units start at approximately $9,000~10,000 for small models aimed at intermittent short-run usage. This provides an economical option for small producers.

- Mid-sized batch cabinet freezers range from $20,000 to $40,000 depending on freezer volume, automated loading systems, and integrated process controls. These are ideal for mid-volume production.

- High-capacity liquid nitrogen cryogenic freezers range from $40,000 up to $70,000 for capacities exceeding 2,000kg/hr or automated cryogenic tunnels. Large food manufacturers benefit from their continuous high throughput.

- Custom-engineered solutions with specialized material handling, data integration, and documentation can be priced up to $100,000.

In addition to base equipment costs, considerations include:

- Ancillary parts like tray racks, trolleys, trays, and probes

- Initial spare parts inventory and consumables

- Shipping and delivery logistics

- Installation and site integration services

Cryogenic Freezer Processing Costs

When evaluating liquid nitrogen cryogenic freezers, key cost considerations include:

- Liquid nitrogen media is the primary consumable cost. Usage varies based on product size, packaging, dwell time, and temperature parameters required. Optimized design and precise controls minimize liquid nitrogen consumption.

- Labor costs are reduced since our automated, PLC-controlled systems require minimal supervision once loaded and activated. Audible and visual alarms alert if intervention is needed.

- Energy consumption is lower compared to traditional mechanical freezing systems since no compressors are needed. Main electrical loads are for circulating fans, sensors, valve actuators, and system controls.

- Maintenance costs are relatively low given the unit's simplicity. The main expenses are periodic replacement of worn parts like seals, hoses, and gaskets on a scheduled preventative basis to maximize uptime.

- Facilities costs for space, utilities, and ancillary equipment like product conveyors and storage.

We work closely with customers during selection and design to predict expected processing costs and ensure the system is tailored for efficient, economical operation. We are experienced in optimizing your cryogenic freezer to maximize quality and throughput while minimizing total operating expenses.

As a leading cryogenic freezer manufacturer of food-grade liquid nitrogen cryogenic freezers for over 30 years, our company offers proven expertise and capabilities:

Our engineering R&D team has deep knowledge of designing specialized ultra-low temperature equipment and systems. We hold over 103 patents related to cryogenic freezing technology and cold chain processes.

Our equipment maintains industry-leading performance benchmarks for freezing speed, temperature uniformity, precision control, and efficiency. We continually refine our designs and production methods.

Our manufacturing facility is ISO 9001 certified. Our equipment meets rigorous CE certification standards. We adhere to stringent quality protocols.

We have extensive experience exporting freezing systems to over 30 countries globally. Our international sales team can manage complex export logistics and documentation.

Long-term partnerships with freight forwarders optimize delivery costs and coordination. This simplifies the global shipping of equipment.

When selecting a cryogenic freezer, choose a manufacturer with proven capability engineering optimized solutions for your goals. We would be delighted to discuss how our expertise and technology can meet your needs.

Nov 13, 2025

Nov 13, 2025

IPv6 network supported

IPv6 network supported