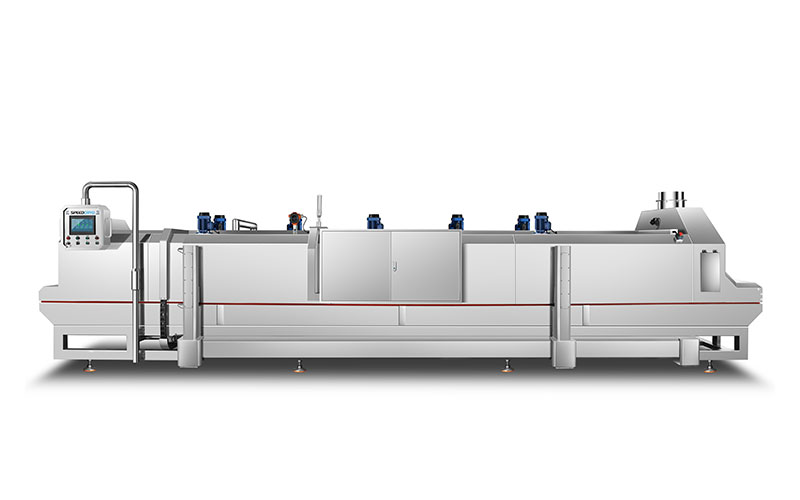

The SPEEDCRYO liquid nitrogen tunnel freezer marks a new generation of cryogenic freezing technology. Combining rapid freezing rates under -120°C with precise temperature control, SPEEDCRYO produces superior quality frozen products with better yield, lower drip loss, smaller ice crystals, and premium texture.

With expert engineering and customizable sizing, SPEEDCRYO is the ideal freezing solution for high-volume producers seeking to improve quality, efficiency, and profits. Plus, our years of experience translates to complete support from design through operation.

Brand:

SPEEDCRYOItem NO.:

JSSD-1112Payment:

T/T, 50% deposit, balance before deliveryProduct Origin:

Guangzhou, ChinaOperating Temperature:

0℃ to -120℃Freezing Time:

5 to 60 minutesRefrigerant:

Liquid Nitrogen (LN2)Capacity:

200 to 1000 kg/hrOverall Width:

1.85m/2.05m/2.25m/2.55m/2.85mOverall Length:

7m/9m/11mOverall Height:

1.9mBelt Material:

SUS304 stainless steelProduct Material:

SUS304 stainless steelInsulation Density:

> 45kg/m3Power:

7-11kW/h, 380/400v, 50/60HzCooling Method:

LN2 atomized direct sprayWarranty:

12 months from the date of receiptCertificate:

CE

IQF stands for Individual Quick Freezing. It is a food freezing technology that freezes food items in a very short time to preserve their quality, texture, and nutrients. Unlike traditional freezing methods, IQF technology allows each individual food item (typically fruits, vegetables, meats, or seafood) to be frozen separately, preventing the formation of large ice blocks. The advantage of IQF equipment is that the freezing process is very fast, taking only a few minutes, which helps maintain the shape, color, smell, and taste of the food. Common examples of IQF foods include fruits like blueberries, strawberries, and peaches; vegetables like corn, peas, and green beans; seafood like shrimp and small fish; meats like chicken and beef; dairy products like pasta and cheese; and grains.

An IQF Tunnel Freezer, also known as a cryogenic tunnel freezer, is one type of IQF equipment. A Liquid Nitrogen IQF Tunnel Freezer specifically uses liquid nitrogen as the refrigerant for ultra-low temperature IQF. SPEEDCRYO's Liquid Nitrogen IQF Tunnel Freezer contains three to five sets of evaporators (nozzles) inside the chamber, each of which can be independently controlled to create multiple different temperature zones. This means that SPEEDCRYO's Liquid Nitrogen IQF Tunnel Freezer allows users to set different temperatures at different positions within the IQF tunnel for more precise control of the cooling rate, thereby reducing the consumption of liquid nitrogen and processing costs while better ensuring the quality of the frozen products.

The IQF tunnel freezer consists of components such as a liquid nitrogen evaporator, nozzles, flow control valves, and fans. During operation, users set the temperature and time on the control system, then continuously place food items at the input end. The food items are then rapidly frozen and output at the discharge end by a conveyor belt. Apart from loading the food, the entire rapid freezing process requires almost no manual intervention and is highly automated. Therefore, many large food enterprises typically choose tunnel-style liquid nitrogen freezers.

A Liquid Nitrogen Individual Quick Freezing (IQF) Tunnel uses liquid nitrogen as a cooling agent to achieve ultra-low temperature rapid freezing, with working temperatures reaching as low as -120 degrees Celsius. In contrast, a standard IQF tunnel freezer uses a compressor for refrigeration (with refrigerants such as R404a, R507, etc.), and typically operates at temperatures ranging from -30°C to -40°C. It is evident that the working temperature of the liquid nitrogen individual quick freezing tunnel is significantly lower than that of a standard IQF tunnel, which allows it to deliver greater production capacity and better quality of frozen products. Under the same production capacity conditions, the volume of a liquid nitrogen IQF tunnel freezer is much smaller than that of a standard IQF tunnel freezer. Additionally, due to the absence of a compressor unit, the liquid nitrogen IQF tunnel freezer has higher operational stability and lower maintenance costs. Therefore, compared to a standard IQF tunnel freezer, the core advantages of a liquid nitrogen IQF tunnel can be summarized as: compact size; higher production capacity; easier maintenance; lower post-sale costs; and higher quality of frozen products.

The SPEEDCRYO liquid nitrogen tunnel has been continuously optimized and market-tested for over 10 years, featuring high reliability and simple maintenance. This tunnel not only enhances productivity but also controls energy consumption efficiently, delivering greater value to users. Below is a detailed description of the product features:

A Liquid Nitrogen Freezer, also known as an Industrial Cryogenic Freezer or LN2 Freezer, is a type of ultra-low temperature refrigeration equipment that uses liquid nitrogen as a cooling source. It can reach temperatures as low as -196°C, with operational temperatures typically ranging from 0°C to -120°C. A complete liquid nitrogen freezing system consists of a Liquid Nitrogen Tank and a Liquid Nitrogen Freezer. The tank stores liquid nitrogen and supplies it continuously to the freezer through a pipeline. The liquid nitrogen is converted to gas in the freezer's evaporation and spray systems, allowing for rapid heat exchange with the items being frozen before being vented outside.

Nitrogen gas is colorless, odorless, non-toxic, harmless, non-flammable, and non-explosive. It does not deplete the ozone layer and makes up 78% of the Earth's atmosphere. Therefore, the exhaust gas (nitrogen) emitted by liquid nitrogen freezing equipment is completely environmentally friendly. Both liquid and gaseous nitrogen, whether during processing or emission, do not cause any environmental pollution. Additionally, during the freezing process, the nitrogen gas sprayed by the spray system quickly envelops the surface of the food, forming an oxygen-free layer that inhibits oxidation, helping to improve the quality of the frozen product.

The minimum operating temperature of a Liquid Nitrogen Freezer can go below -100°C. It is highly efficient, compact in size, and has a large production capacity, all while being completely eco-friendly. As a result, the application of liquid nitrogen freezing equipment is becoming increasingly widespread, especially in the high-end food ingredient sector, where more companies are choosing to use liquid nitrogen freezers to enhance the quality of their frozen products.

The evaporation temperature of liquid nitrogen is -196°C, and the working temperature of a typical liquid nitrogen freezing machine ranges from 0°C to -120°C. The lower working temperature allows the freezing process to quickly pass through the maximum ice crystal growth zone (i.e., from 0°C to -5°C). The maximum ice crystal growth zone refers to the temperature range between 0°C and -5°C, where 80% of the water inside the food turns into ice crystals. The faster the freezing process passes through this zone, the smaller and more uniform the ice crystals formed; the longer the process stays in this zone, the larger the volume of the ice crystals. The working temperature is a key factor in determining the size of the ice crystals inside the food. The ultra-low working temperature allows the freezing process to be completed more quickly, resulting in finer and more uniform ice crystals. Small ice crystals are less likely to damage cell walls and will preserve the food's original nutritional content to the greatest extent. If the freezing time is prolonged and large ice crystals are formed, it will significantly damage the food's cell walls, leading to a loss of nutrients. Therefore, the freezing temperature is an important factor in determining the quality of frozen products. The core advantage of liquid nitrogen freezing machines is to use ultra-low working temperatures to improve the quality of frozen products. Additionally, liquid nitrogen is a completely environmentally friendly refrigerant. The waste gas it emits (i.e., nitrogen) is a non-toxic, colorless, odorless, non-flammable, non-explosive inert gas that causes no harm to food, human health, or the atmospheric environment.

The above points highlight the greatest advantage of liquid nitrogen freezing equipment, which is to enhance the quality of frozen products. This ultra-low temperature freezing technology is particularly suitable for high-value and easily damaged food items, such as whole durian, durian pulp, salmon, oyster, sea cucumber, etc. During the durian harvest season, ripe durians can be rapidly frozen in large quantities and then stored at around -20°C, remaining unspoiled for up to a year. SPEEDCRYO has completed many durian freezing projects in Southeast Asian countries. Our clients use liquid nitrogen freezing machines operating at -120°C to freeze whole durians or durian pulp, which can then be stored in cold storage for half a year or even a year while still maintaining their original taste and color.