SPEEDCRYO® 500KG Semi Contact Plate Freezer is an innovative food quick-freezing equipment, which can use both air cooling and contact freezing principles to achieve efficient freezing effect. The freezing capacity of this equipment is 500KG per 4 to 6 hours, suitable for quick-freezing of various foods. This equipment uses 8 layers of high-quality aluminum plates of 2000x900mm, each layer can hold 6 trays of 400x600x80mm, a total of 48 trays. The external dimensions of this equipment are 3900x1250x1950mm, small footprint, easy installation. The working temperature of this equipment is -40°C, which can ensure the quality and nutrition of food. The compressor of this equipment adopts Refcomp SBC4-160E model, which can also be replaced by BITZER compressor according to customer’s needs.

Brand:

SPEEDCRYODimensions (mm):

3900x1250x1950Capacity:

500KG/4-6HCompressor Unit:

Refcomp SBC4-160ERefrigerant:

R507Cooling System:

Water coolingAluminum Plate Size:

2000x900mmLayers of Aluminum Plate:

8 layersPower:

18.5KWWorking Temperature:

-40 degrees CelsiusCooling Tower:

15TCondensing Temperature:

40 degrees CelciusInsulation Layer:

150mmMaterial:

SUS304 stainless steelQuality Warranty:

12 monthsService Language:

English, Chinese

The Contact Plate Freezer is a device that utilizes a combination of aluminum plates and cold air for rapid freezing of food. It is classified into two types: the Semi-Contact Plate Freezer and the Full-Contact Plate Freezer.

The operating principle of the Semi-Contact Plate Freezer involves close contact between the aluminum plate and the lower surface of the food, facilitating rapid heat conduction and dissipation. Simultaneously, axial flow fans direct cold air towards the upper surface of the food, creating a dual cooling effect. The Full-Contact Plate Freezer sandwiches the food between two aluminum plates, ensuring complete adherence and maximizing heat exchange efficiency.

A Contact Plate Freezer typically consists of components such as a freezing chamber, aluminum plates, refrigeration units, and axial flow fans. This technology offers numerous advantages, including high freezing efficiency capable of rapidly lowering food temperature to below -18°C within a short time frame. Additionally, the manufacturing cost is controllable due to standardized components like aluminum plates and axial flow fans. The resulting frozen products exhibit high quality with minimal loss, preserving the food's moisture and nutritional content. As a result, Contact Plate Freezers have found widespread applications in the bulk freezing of seafood, meat, vegetables, pasta, and other products.

The SPEEDCRYO® Semi Contact Plate Freezer is a food rapid freezing device that combines air cooling and contact freezing methods. It involves the contact of the lower surface of the food with an aluminum plate (the food is placed on an aluminum tray or stainless steel tray) to enhance freezing speed. Simultaneously, an axial flow fan within the equipment's chamber generates airflow circulation, boosting heat exchange efficiency and aiding in the removal of water vapor and frost generated during the freezing process.

Positioned on the side of the freezing chamber, the axial flow fan generates internal airflow circulation, enhancing heat exchange efficiency, and aiding in the removal of water vapor and frost during the freezing process.

The control system includes an electrical control cabinet, temperature sensors, pressure sensors, etc. Its role is to monitor and control the operation of the freezer, ensuring safety and stability. The control system can also implement hot gas defrosting, quickly detaching products from the aluminum plate to enhance production efficiency.

The freezing chamber is constructed with double-sided SUS304 stainless steel and polyurethane foam, ensuring high hygiene standards and low corrosion risks. The thickness reaches 150mm, and the chamber features multiple layers of aluminum plates and axial flow fans. There are fixed gaps between each aluminum plate for product placement (total gap of 150mm, maximum acceptable tray height of 110mm, customizable).

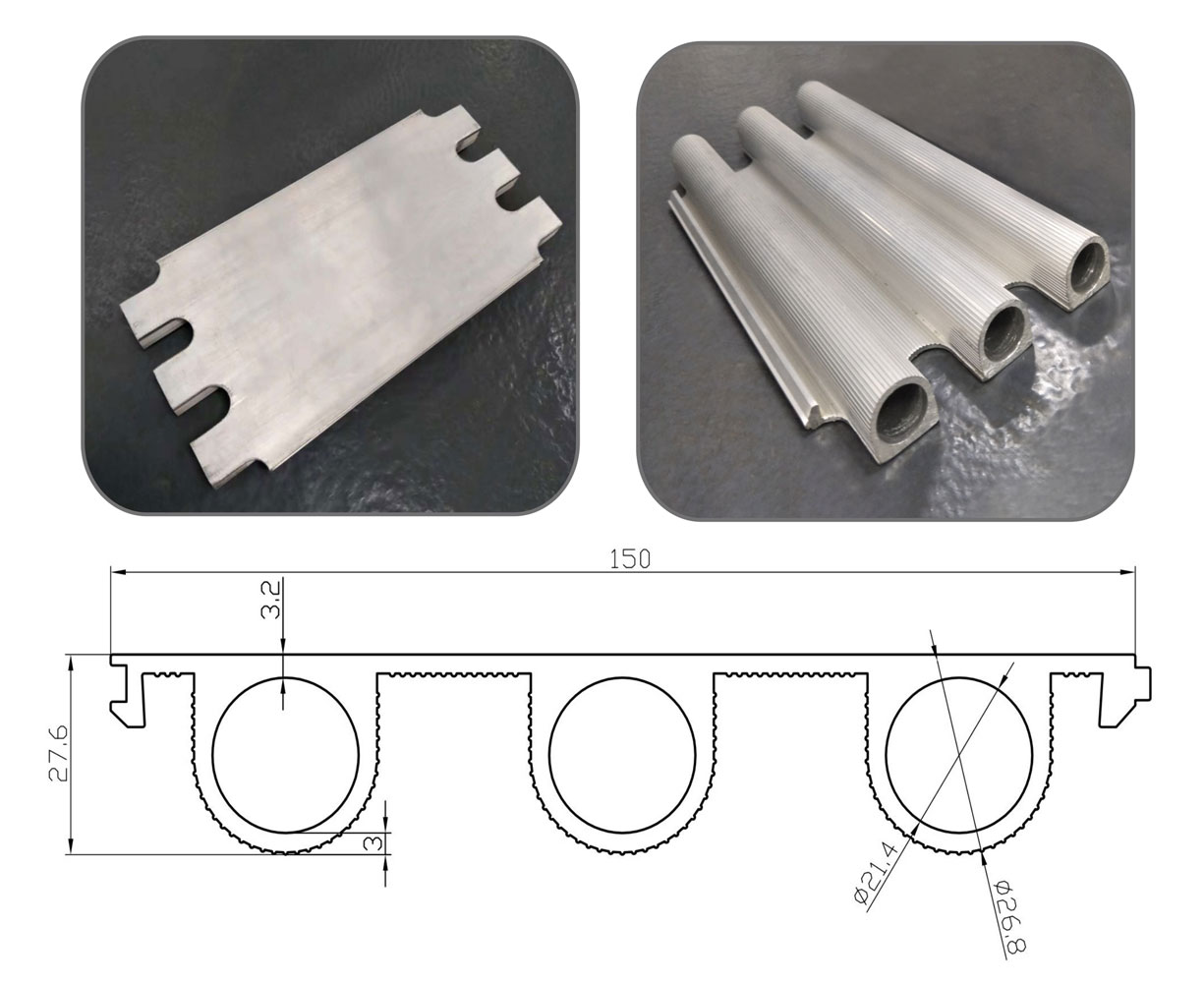

The core component of SPEEDCRYO® Semi Contact Plate Freezer is the aluminum plate, made from high-purity aluminum alloy with excellent thermal conductivity and corrosion resistance. The top surface of the aluminum plate is flat, while the bottom features an aluminum tube structure, designed to optimize air convection and cold radiation, resulting in faster freezing compared to air-blowing freezers. The high-quality aluminum plate evaporator from SPEEDCRYO® is suitable for both onshore and marine rack freezing storage. The SPEEDCRYO® 500KG semi contact plate freezer is equipped with 8 pieces of 2000x900mm aluminum plates, each accommodating 6 trays of 400x600x80mm, allowing for 48 trays per batch.

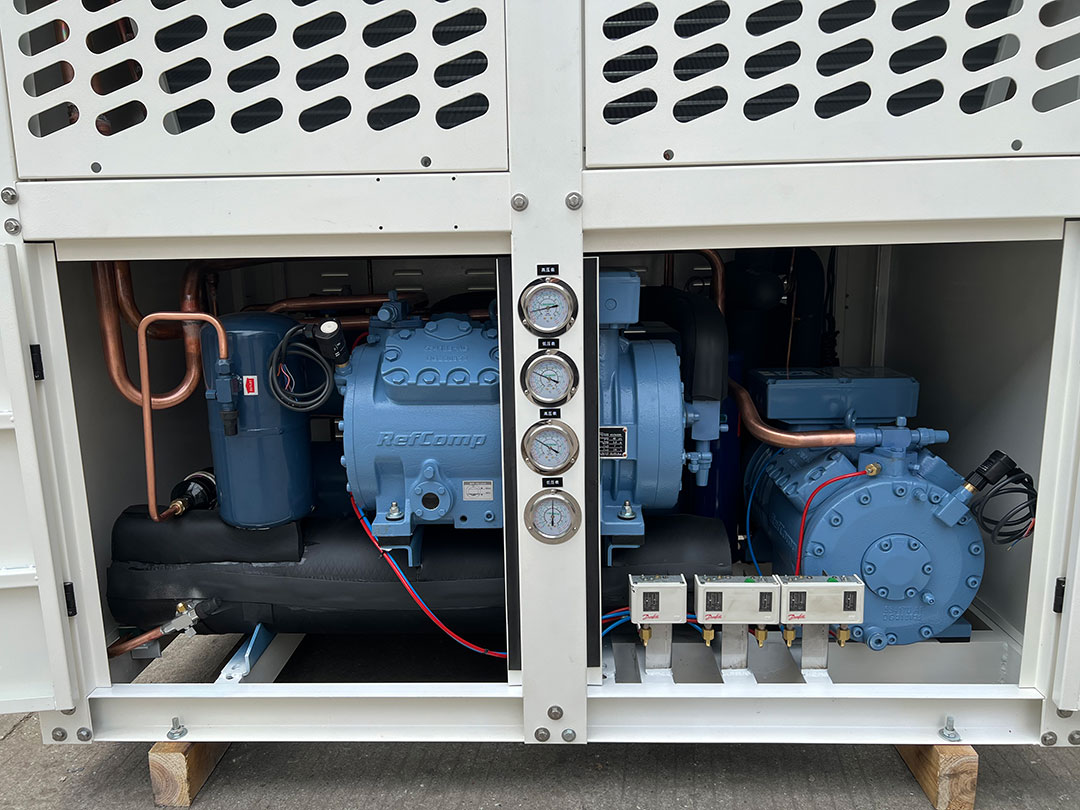

The refrigeration system includes components such as a compressor, condenser, evaporator, drying filter, expansion valve, etc. Its purpose is to circulate refrigerant and provide refrigeration capacity. The refrigerant enters the aluminum plates through refrigeration pipes, extracting heat from the product. It then releases heat through the condenser, lowers pressure through the expansion valve, enters the evaporator, completing a freezing cycle. SPEEDCRYO® semi contact plate freezer uses a Refcomp refrigeration unit known for stability and reliability, offering a lower price compared to BITZER units. Upon request, it can be replaced with a BITZER compressor unit.

| (1) Specifications of Refrigeration System | |

| Freezing capacity | 500kg/4-6H |

| Compressor | Refcomp, SBC4-160E |

| Cooling capacity | 15KW |

| Compressor running power | 14KW |

| Compressor running current | 23A |

| Refrigerant | R507 |

| Voltage | 380v/50hz/3p |

| Cooling system | Water cooling |

| Input material temperature | 8℃ |

| Center temperature | -18℃ |

| Freezing temperature | -40℃ |

| Ambient temperature | 30℃ |

| Condensing temperature | 40℃ |

| Cooling fan | 7#x1, 1.5KW |

| Cooling tower | 15T |

| Circulating water pump | 1.5KW |

| Refrigeration unit size | 1250x650x1950mm |

| (2) Specifications of Contact Plates: | |

| Number of Layer | 8 layers |

| Plate size | 2000x900mm |

| Space between each layer | 150mm |

| Plate material | Aluminum plate |

| Size of tray | 600x400x80mm |

| Weight of each tray | 10kg |

| Trays loaded per layer | 6 trays loaded per layer |

| Total tray capacity | 48 trays loaded per cycle |

| (3) Specifications of PU Panels: | |

| Overall length | 3900mm |

| Overall width | 1250mm |

| Overall height | 1950mm (including a base with a 100mm extension) |

| PU panel thickness | 150mm |

| Pu panel material | 304 double-sided stainless steel |

| Number of doors | 2 doors +1 small maintenance door |

The Contact Plate Freezer and Air Blast Freezer both fall under the category of indirect freezing equipment, utilizing a cooling medium to exchange heat with food for the purpose of freezing. The key difference lies in the choice of the cooling medium; the Air Blast Freezer employs air, while the Contact Plate Freezer uses both aluminum plates and air as cooling media.

In the Semi-Contact Plate Freezer, aluminum plates are positioned beneath the food, ensuring close contact to enhance heat conduction efficiency. Simultaneously, cold air is blown over the top of the food, facilitating convective heat exchange. The Full-Contact Plate Freezer sandwiches the food between two aluminum plates, maximizing heat conduction efficiency by ensuring contact with both upper and lower surfaces.

In contrast, the Air Blast Freezer relies solely on air convection for heat exchange, resulting in lower efficiency. Therefore, within the same freezing time frame, the Contact Plate Freezer can achieve a lower center temperature in the food, reducing moisture loss and minimizing frost formation.

The Contact Plate Freezer is well-suited for large-scale, high-efficiency, and high-quality industrial food freezing production lines, especially for foods requiring rapid cooling while preserving original flavors, preventing deformation, and avoiding discoloration. Due to the necessity of high-quality, high-strength, and highly thermally conductive aluminum plates as the main components, the manufacturing cost of the contact plate freezer is higher, making the contact plate freezer price more expensive compared to the Air Blast Freezer.

The Semi Contact Plate Freezer and Full Contact Plate Freezer are both types of Contact Plate Freezer or Cold Plate Freezer. The Contact Plate Freezer is primarily used for the bulk freezing of seafood, meat, vegetables, pasta, and similar products.

The Semi Contact Plate Freezer combines both air cooling and contact freezing methods. It involves the contact of the lower surface of the food with an aluminum plate (the food is placed on an aluminum tray or stainless steel tray). This enhances the freezing speed, and concurrently, an axial flow fan within the equipment's chamber generates airflow circulation, boosting heat exchange efficiency. This process also aids in removing water vapor and frost generated during the freezing process.

On the other hand, the Full Contact Plate Freezer utilizes the upward and downward movement of the internal aluminum plates to ensure full contact between the upper and lower surfaces of the product and the plates, achieving efficient heat exchange.

In the freezing process of the Full Contact Plate Freezer, food is placed between two aluminum plates. The high thermal conductivity of aluminum plates results in a rapid freezing speed compared to air. In contrast, the freezing process of the Semi Contact Plate Freezer primarily involves placing the food directly on the aluminum plate. The upper part of the food relies on forced air circulation, combining thermal conduction and convection, resulting in a slightly slower freezing speed compared to full contact freezing.

However, the Semi Contact Plate Freezer has a simpler mechanism (lacking hydraulic devices and the need to control the upward and downward movement of aluminum plates). As a result, it is more economical, has a lower failure rate, and is more convenient to use.

Founded in 2014, Guangzhou Speed Refrigeration Equipment Co., Ltd, operating under the brand SPEEDCRYO, is a leading manufacturer of food freezing equipment. With a modern manufacturing facility spanning 35,000 square meters, the company has secured over 100 patents in cold chain technology and has been recognized as a Chinese national high-tech enterprise and an SRDI enterprise (Specialized, Refinement, Differential, Innovation).

Specializing in the research and development, production, and sales of food quick-freezing equipment, SPEEDCRYO offers a diverse range of products, including Contact Plate Freezers, Air Blast Freezers, IQF Tunnel Freezers, Liquid Nitrogen Freezers, and more. Our products are exported to over 20 countries, including Estonia, Cyprus, Bulgaria, the United States, Canada, Peru, Kenya, Thailand, Vietnam, Malaysia, the Philippines, Indonesia, Saudi Arabia, and others.

Our company boasts a professional export business team proficient in English, providing comprehensive services. We can dispatch engineers to over 20 countries to offer on-site installation guidance, operational training, and other services. With a commitment to innovation, quality, and global service, SPEEDCRYO is dedicated to shaping the future of the food freezing industry.

Contact our expert today for detailed discussion!