PRODUCT MAIN SPECIFICATIONS

| Model No.: |

JSGS-1800L |

| External Dimensions: |

2060x1600x2130 mm (LxWxH) |

| Internal Dimensions: |

1400x750x1450 mm |

| Working Temperature: |

0 to -120 degrees Celcius |

| Average Capacity: |

250-550 KG/H

|

| Power: |

1.0KW, 220v/380v |

| ACCESSORY |

| Shelf: |

1 units, SUS304 |

| Trolley: |

1 units, SUS304 |

| Tray: |

48 pieces, 400x600 mm, SUS304 |

| Inter-Layer Spacing: |

70 mm(Optional 100mm) |

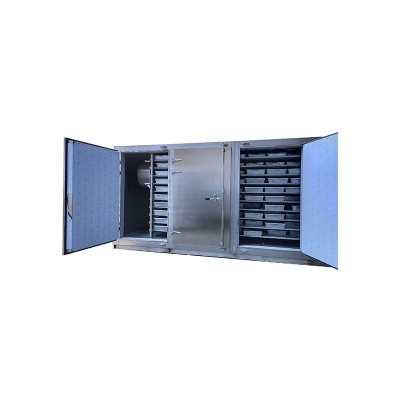

SPEEDCRYO® Cabinet-Type Liquid Nitrogen Freezer JSGS-1800L offers a standard tray + shelf and a trolley. The tray + shelf setup is suitable for most common ingredients, such as seafood, fruits, baked goods, and prepared foods. The shelf spacing can be adjusted according to the customer's food needs.

ACCESSORY

-

Shelf

Inter-layer spacing 70mm, 16 trays per shelf. Inter-layer spacing adjustable.

-

Trolley

Trolley for loading, discharging and moving the shelves.

-

Tray (400x600mm)

High quality SUS304 stainless trays, 48 pieces of tray loaded per batch

Overview of Liquid Nitrogen Blast Freezing

Liquid nitrogen blast freezing is an innovative method of ultra-low temperature freezing using extremely cold liquid nitrogen. This technology is used for food preservation and processing applications where rapid freezing for quality and efficiency is needed.

What is a Blast Freezer?

A blast freezer refers to any freezer that chills products very quickly to cryogenic temperatures using cold gases or liquids. Liquid nitrogen blast freezers utilize the ultra-low temperature of liquid nitrogen, which reaches -320°F/-196°C, for cryogenic freezing. The liquid nitrogen rapidly absorbs heat from products immersed or conveyed through the frigid nitrogen vapors or liquid.

Temperature of Liquid Nitrogen Blast Freezers

The operating temperature inside liquid nitrogen blast freezers reaches as low as -320°F/-196°C. However, product core temperatures for full freezing normally range from -0.4°F/-18°C down to -90°F/-68°C depending on dwell time. Fast chilling to at least -0.4°F/-18°C enables rapid preliminary stabilization prior to transfer to storage freezers. This extreme cold facilitates freezing times measured in minutes rather than hours.

Applications for Liquid Nitrogen Blast Freezing

Cryogenic Blast Freezer for Fish - Our liquid nitrogen blast freezers are especially well-suited for cryogenic freezing of fish. The direct liquid nitrogen contact and ultra-fast temperatures freeze fillets rapidly while minimizing damage to cellular structures. This retains premium quality attributes like texture and moisture. For example, salmon fillets can be hardened completely in just 8-12 minutes, with shellfish and shrimp freezing even faster. Liquid nitrogen is a perfect medium for cryogenic blast freezing of fish products.

Prepared Foods - Liquid nitrogen blast freezing prevents damage to prepared foods that would occur under slow freezing. Rapid chilling preserves flavors, appearance, and integrity that would otherwise be lost. It also avoids freezer burn. Delicate sauces, gravies, and condiments freeze solidly with minimal separation.

Ice Cream - Hardening ice cream from soft serve to frozen requires ultra-fast freezing rates to lock in a smooth, creamy texture without damaging ice crystals. Liquid nitrogen can harden ice cream in just 10-40 minutes thanks to direct contact at -320°F. This produces a superior mouthfeel compared to plate freezers.

What is the cost of blast freezing process?

Liquid nitrogen freezer expenses can be categorized into:

- Variable Cryogen Usage - This is the ongoing liquid nitrogen media cost, which varies based on production throughput and efficiency. Optimizing freezing parameters helps minimize nitrogen consumption.

- Energy Demand - Electricity is needed to run components like circulating fans, conveyors, and controls.

- Maintenance Overhead - This includes the replacement of common wear parts like belts, filters, probes over time. Also covers periodic preventative maintenance labor for cleaning and servicing.

- Direct Labor - Personnel costs for activities like loading, unloading, monitoring batch freezing cycles and liquid nitrogen levels.

- Equipment Expenses - The original and ongoing costs of the blast freezing unit itself including financing/depreciation and facility space.

Careful analysis of each expense category allows food processors to identify opportunities to maximize the value of liquid nitrogen blast freezing. Improving efficiency, throughput, and product quality helps offset operating costs.

Price of Liquid Nitrogen Blast Freezers

Pricing for industrial liquid nitrogen blast freezers ranges from approximately $10,000 up to $70,000 depending on capacity, degree of automation, and configurations.

We offer various promotional incentives for new and repeat customers:

- Volume Discounts - Qualified buyers making large equipment purchases may request our general manager to provide customized bulk pricing. This rewards major investments in our blast freezers.

- Complimentary Consumables - For customers using preferred payment terms like 100% upfront, we sometimes include free bonus items like gloves, racks, or probes to support new equipment roll-out.

- Extended Warranties - Repeat customers running existing units under proper maintenance may qualify for 2-3 year extended warranties when purchasing additional blast freezers. This provides assurance of long-term reliability and support.

Industrial Liquid Nitrogen Freezing Equipment

Our company manufactures a complete range of industrial liquid nitrogen blast freezer equipment for high-volume food processing. Available units include:

- Batch immersion cabinets from 50kg/hr up to 3,000kg/hr

- Automated conveyorized cryogenic tunnels from 1,000kg/hr to 15,000kg/hr

- Custom freezing solutions with automated loading/unloading, data logging, mobility

Built to meet rigorous industrial standards, our freezers deliver precise process control, efficient liquid nitrogen usage, and sanitary construction. With freezing temperatures down to -184°F/-120°C, fast chilling for quality and efficiency is achieved. We engineer robust, specialized equipment to match your exact processing needs and throughput.

Contact our experts today to explore how liquid nitrogen blast freezing can benefit your specific operation. We will collaboratively determine the ideal equipment specifications, capacity, and configurations to maximize freezing performance, end-product quality, and budget efficiency for your needs. Our goal is to help clients leverage the many benefits of liquid nitrogen blast freezer technology for their unique production requirements.

APPLICATIONS OF SPEEDCRYO® LIQUID NITROGEN FREEZER

The liquid nitrogen cabinet freezer from SPEEDCRYO is extensively utilized for freezing whole durians, durian pulp, seafood such as fish, shrimp, crabs, sea cucumbers, abalone, Arctic surf clams, and salmon, as well as baked goods like egg tarts, durian cakes, and ice cream, in addition to prepared foods. With an operating temperature range from 0°C down to -120°C, it effectively fulfills the rapid freezing requirements for most food items. Despite its small footprint, it offers a higher capacity, low initial and maintenance costs, and user-friendly operation. The extremely low temperatures facilitate the formation of smaller ice crystals, resulting in superior quality frozen products and extended shelf life. Foods frozen using SPEEDCRYO's liquid nitrogen freezer maintain their original color, texture, and nutritional value almost as if they were fresh upon thawing. As a result, an increasing number of food companies, particularly those specializing in premium products, are transitioning to liquid nitrogen freezing technology, moving away from traditional compressor-based freezing methods.

Nov 13, 2025

Nov 13, 2025

IPv6 network supported

IPv6 network supported