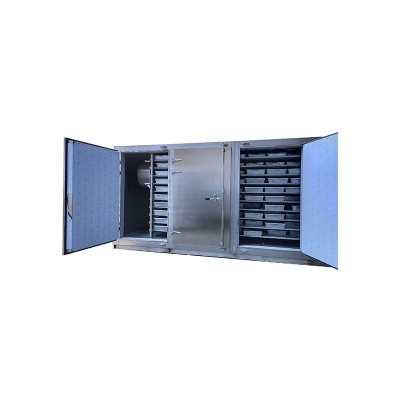

PRODUCT MAIN SPECIFICATIONS

| Type: |

Liquid Nitrogen Freezer |

| Model No.: |

JSGS-4000L |

| External Dimensions: |

2720x1940x2370 mm (LxWxH) |

| Internal Dimensions: |

1170x1550x1750 mm ( x 2 cabinets) |

| Working Temperature: |

0 to -120 degrees Celcius |

| Average Capacity: |

400-800 KG/H

|

| Power: |

1.5KW, 380v/400v, 3P |

| ACCESSORY (A) - FOR NORMAL FOODS |

| Shelf: |

2 units, SUS304, 910x720x1550 mm |

| Trolley: |

2 units, SUS304 |

| Tray: |

30 pieces, 850x700 mm, SUS304 |

| Inter-Layer Spacing: |

100 mm |

| ACCESSORY (B) - FOR WHOLE DURIAN |

| Durian Cart: |

2 units, SUS304 |

| Trolley: |

2 units, SUS304 |

SPEEDCRYO® Cabinet-Type Liquid Nitrogen Freezer JSGS-4000L provides two kinds of accessories: a standard tray along with a shelf and a durian cart. The combination of the tray and shelf is ideal for the majority of ordinary ingredients, like seafood, fruits, baked goods, and ready-made foods. The durian cart is specially crafted for freezing entire durians. Users have the option to select the suitable accessory according to their requirements or acquire both types of accessories concurrently.

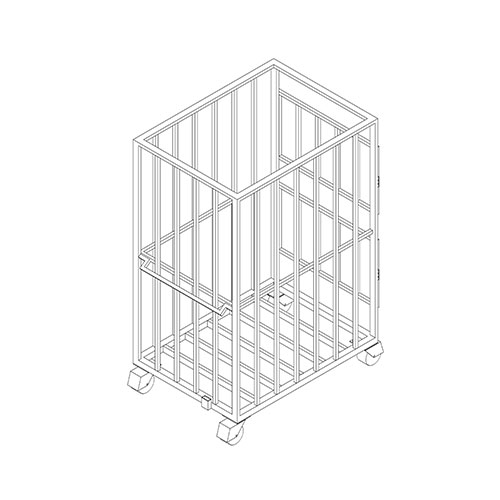

ACCESSORY (A) - FOR NROMAL FOODS

-

Shelf

Inter-layer spacing 100mm, 30 trays per shelf. Inter-layer spacing adjustable.

-

Trolley

Trolley for loading, discharging and moving the shelves.

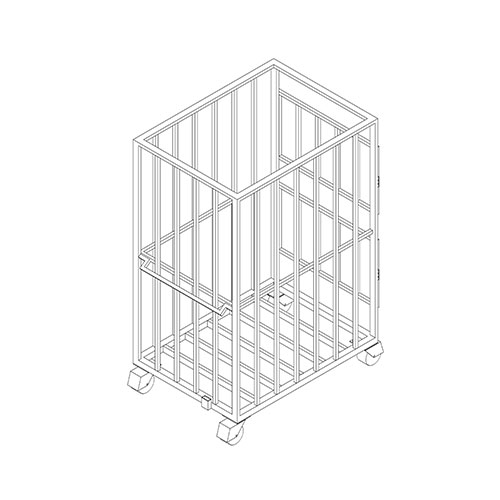

ACCESSORY (B) - FOR WHOLE DURIAN

-

Durian Cart

SUS304 durian cart, 700-800 kg of whole durian can be loaded in each cart.

-

Trolley for Durian Cart

SUS304 trolley, for loading, discharging and moving durian carts.

APPLICATIONS OF SPEEDCRYO® LIQUID NITROGEN FREEZER

SPEEDCRYO's Liquid Nitrogen Flash Freezers is extensively utilized for freezing whole durians, durian pulp, seafood (such as fish, shrimp, crabs, sea cucumbers, abalone, Arctic surf clams, salmon, etc.), baked goods (including egg tarts, durian cakes, ice cream, etc.), prepared foods, and many others. It operates within a temperature range from 0°C to -120°C, fulfilling the rapid freezing demands of the majority of foods. Despite its small size, it provides higher capacity, has low initial investment expenses, low maintenance costs, and is user-friendly. The extremely low operating temperatures lead to smaller ice crystals, superior quality of frozen products, and a longer shelf life. Foods frozen by SPEEDCRYO's liquid nitrogen freezer maintain their color, texture, and nutritional value close to their fresh condition after thawing. As a result, more food enterprises, particularly those handling high-end products, are increasingly adopting Liquid Nitrogen Freezing Technology to substitute traditional compressor-based freezing equipment.

What is Flash Freezer?

A flash freezer rapidly freezes products to cryogenic temperatures under -18°C very quickly. This allows much faster freezing than traditional mechanical systems. Liquid Nitrogen Flash Freezers use ultra-cold liquid nitrogen at -196°C/-320°F to achieve flash-freezing conditions. Items are immersed in or conveyed through liquid nitrogen for rapid conductive heat transfer.

Flash freezers can chill products to a frozen state in minutes or even seconds, depending on size. This minimizes exposure time and prevents large damaging ice crystals from forming internally. The result is smaller ice crystals, reducing cellular damage and quality degradation.

Temperature of Liquid Nitrogen Flash Freezers

The operating temperature inside Liquid Nitrogen Flash Freezers reaches -196°C/-320°F. However, most food products are removed after reaching optimal freezing temperatures between -18 and -40°C. Extended exposure risks over-freezing and freezer burn.

Liquid nitrogen's lower boiling point compared to mechanical systems provides a larger temperature gradient for faster heat extraction. This enables exceptional flash freezing speed measured in minutes versus hours with traditional freezers.

Benefits of Industrial Liquid Nitrogen Flash Freezers

Industrial liquid nitrogen flash freezing systems provide major advantages:

- Faster freezing preserves quality attributes like texture, moisture, and visual appeal.

- Higher throughput increases production capacity and efficiency.

- Flexible freezing of diverse products and mixed loads.

- Improved food safety with no contamination risk from coils or plates.

- The compact, self-contained footprint for space savings versus mechanical systems.

How to Buy Flash Freezer?

Purchasing a flash freezer involves considerations like:

- Required production capacity and hourly/daily throughput.

- Available installation space and degree of automation needed.

- Local access to liquid nitrogen supply and delivery services.

- Operating budgets for cryogen supply, maintenance, and labor.

Work with an experienced flash freezer manufacturer to select the model and features optimized for your needs. Engage their engineering team early in the design process to customize your system.

Liquid Nitrogen Flash Freezing Technology

Liquid nitrogen provides a number of technological advantages for industrial flash freezing:

- The ultra-low boiling point of -196°C/-320°F for instant freezing potential.

- Efficient cooling via conductive heat transfer and phase change.

- No mechanical refrigeration system is needed, reducing complexity.

- Inert, non-toxic, and readily available in bulk supply.

- Customizable computerized process control for precision freezing.

The combination of extremely cold temperatures and advanced automation allows Liquid Nitrogen Flash Freezers to maximize both product quality as well as process efficiency.

Liquid Nitrogen Flash Freezing Technology

Our company provides a full range of industrial cabinet and tunnel flash freezers engineered specifically for the food industry. Capacities from 50kg/hr to 3,000kg/hr are available.

We customize units to match the required throughput, space constraints, automation needs, and budget. This allows food processors to achieve ideal freezing results whether producing small batches or high-volume production runs.

Contact our experts today to determine the perfect flash-freezing solution for your manufacturing needs. Improve quality, efficiency, and safety with properly engineered industrial liquid nitrogen flash-freezing equipment.

Nov 01, 2024

Nov 01, 2024

IPv6 network supported

IPv6 network supported